Silga, almost the first in Europe to invest in biological wastewater treatment

The biological industrial waste water treatment plant was necessary for the removal of nitrogenous compounds. The existing chemical-physical purification plant was indispensable for removal of heavy metals and toxic substances (such as cyanides), but it was unable to bring us within the legislative parameters for nitrogen compounds, such as ammoniacal nitrogen (the limit is 30ppm), nitric nitrogen (30ppm limit) and nitrous nitrogen (0.6ppm limit).

The biological industrial waste water treatment plant was necessary for the removal of nitrogenous compounds. The existing chemical-physical purification plant was indispensable for removal of heavy metals and toxic substances (such as cyanides), but it was unable to bring us within the legislative parameters for nitrogen compounds, such as ammoniacal nitrogen (the limit is 30ppm), nitric nitrogen (30ppm limit) and nitrous nitrogen (0.6ppm limit).

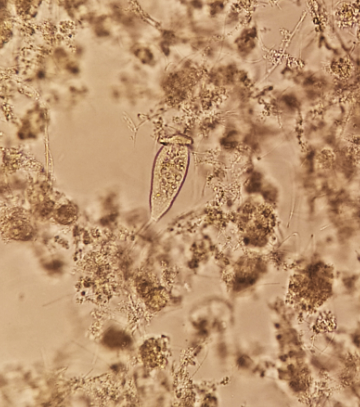

Biological plants have always been used for the treatment of municipal wastewater, or wastewater from the food industry, because they have a high input of organic substances, a fairly constant flow and pollutant load, and essentially no toxins.

These conditions are important for the success of the nitrogen and phosphorus removal process, control parameters for areas defined as “sensitive”. These conditions are difficult to meet for an industrial metal treatment effluent. In fact, an excess of hypochlorite or sodium sulphide (used respectively for neutralising cyanides and precipitating metals) would be enough to annihilate or otherwise compromise the bacterial activity underlying the process. Not to mention the fluctuations in pH, temperature and flow rate to which galvanic industrial wastewater is naturally predisposed.

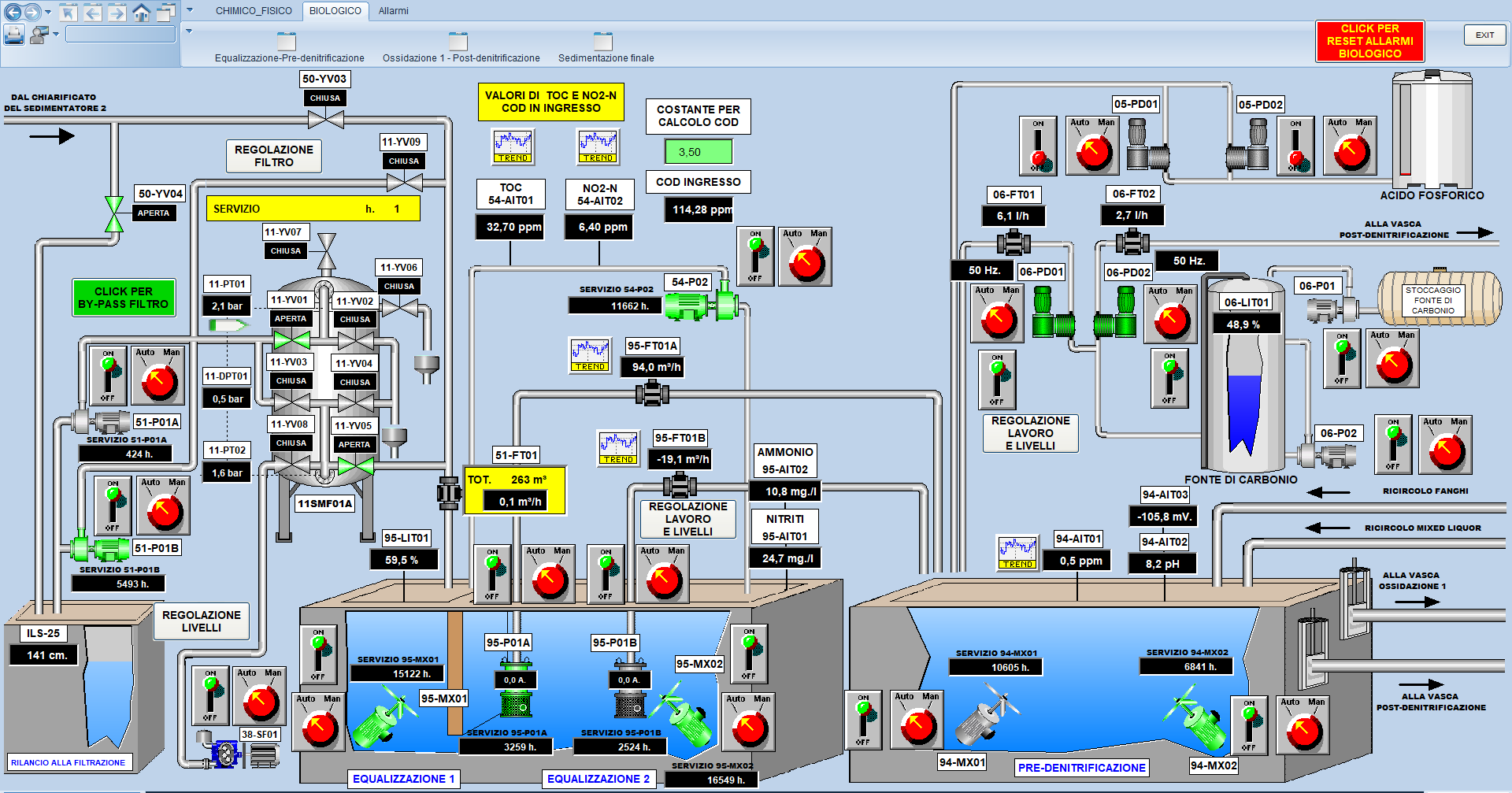

Silga spa has nevertheless decided to invest in this ambitious and innovative project and take the lead. The reasons repay the economic and, above all, technical effort: a final post-denitrogen treatment has been added to the classic anaerobic-aerobic sequence, molasses as a constant carbon source and a multitude of automatic controls for physical and chemical parameters (e.g. dissolved oxygen, nitrogen, TOC, pH, redox potential, chlorides…).

The biological purifier allows us to almost totally break down nitrous and nitric nitrogen and considerably limit ammoniacal nitrogen, which are the basis of surfactants and other nitrogenous products essential for maintaining the high technical and aesthetic standards of galvanised products.

This allows us to use them “without care”, and to maintain the wide range of finishes and solutions. That’s not all: the quality of the wastewater treated downstream of the biological purifier is so high that it allows us to reuse much of it in the process, with considerable water savings, considering that the wastewater has an average daily flow rate of 60 mc/h (maximum flow rate 120 mc/h).

Considering that the current percentage of recycling is 10%, the goal is to improve more and more this percentage.

Technical notes:

Equalization tank: chemical-physical wastewater arrival

Denitro, oxidation and post-denitro tank: tot. 1500 mc

Settling tank: Tot 2000 mc