Silga’s Galvanizing division realizes treatments of galvanizing and zinc-nickel plating on various metal substrates, as well as a series of accessory pre and post treatments to integrate the base treatments.

The division has 25 work units and uses automatic multi-program plants managed through innovative software systems for static and barrel processing of plating. The inbound material is encoded for part number, quantity and processing code, ensuring traceability throughout the industrial flow from arrival to final delivery to the customer. The strength of the department are the innovative treatments and the high production capacity.

Plants and materials

The Galvanizing division has several automatic plants with multi-program systems; the material advancement run in self-management through innovative software that allows to monitor and maintain constantly temperatures, times and current of processes, in addition to the progress of orders production.

Static plants (frame): nr. 3 multi-program automatic plants managed by innovative software

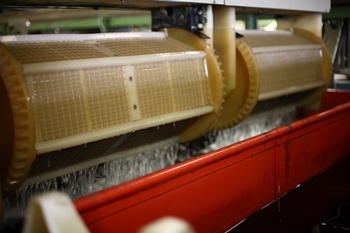

Barrel plants: nr. 3 multi-program automatic plant managed by innovative software

The daily productivity is 120,000 sdm/day for static plants and 900 quintal/day for barrel plants.

The processes of galvanizing and zinc-nickel can be applied on the following metal substrates

Steel and its alloys: hard and soft steels, stainless steels, alloy steels, cast irons, steels and heat-treated surface, etc.;

Copper and its alloys: brass, copper and bronze;

Zamak.